Color printing has become an indispensable aspect of our visual world, shaping how we perceive and interact with information. CMYK color models are an integral part of the packaging and printing field. Understanding the CMYK color model will give you a better understanding of your packaging. In this article, we delve into the rich history, advantages, techniques for color accuracy, diverse applications, and additional insights surrounding the CMYK color mode.

| Name | Meaning | Mechanics | Function |

| C | Cyan is a blue-green color | It absorbs red light | an essential component for creating greens and blues |

| M | Magenta is a purplish-red hue | It absorbs green light | plays a vital role in producing shades of purples, pinks, and reds |

| Y | Yellow | It absorbs blue light | crucial for creating various warm tones, including oranges, yellows, and browns |

| K | K stands for Key, represents black | It absorbs all light | contributing to enhanced contrast, detail, and overall color accuracy in printed materials |

1. The Role of Black (K) in CMYK Printing:

- Enhanced Contrast and Detail:

Although theoretically, the combination of cyan, magenta, and yellow should produce black, in practical applications, it’s difficult for cyan, magenta, and yellow to overlay and form true black. Instead, this combination often results in very dark brown shadows. By adding black ink separately, printers can achieve deeper blacks and more accurate grayscale reproduction.

- Conservation of Ink and Cost:

Using black ink exclusively for text and line art helps conserve ink and reduces printing costs. Compared to using a combination of cyan, magenta, and yellow to create black, which may require more ink and result in a less precise outcome, using black ink separately offers efficiency and cost-effectiveness in printing.

- Sharper Text and Graphics:

When printing text and line art, using black ink exclusively ensures sharper results. The use of black ink for fine details and text helps maintain clarity and legibility, especially in small fonts and intricate designs.

- Neutralizing Color Casts:

Incorporating black ink can help neutralize color casts and improve the overall color balance in printed materials. It provides a stable foundation that complements the cyan, magenta, and yellow inks, contributing to more accurate color reproduction.

2. Exploring the Rich History of CMYK

In the dynamic world of printing and design, the CMYK color model stands as a cornerstone, enabling the reproduction of vibrant and accurate colors in various printed materials. The history of CMYK is a fascinating journey that spans centuries, marked by scientific discoveries, technological advancements, and creative innovations.

- Origins of Color Theory:

The roots of CMYK can be traced back to ancient times when artists and scholars began to explore the principles of color mixing and perception. Early theories of color, including those proposed by Aristotle and Leonardo da Vinci, laid the groundwork for understanding how colors interact and combine to form new hues.

- The Birth of the Color Printing Process:

The invention of the printing press in the 15th century revolutionized the dissemination of knowledge and information. However, early printing techniques were limited to monochromatic or single-color prints, restricting the reproduction of colorful images and illustrations.

- Cyan, Magenta, and Yellow:

In the 19th century, scientists and artists began to experiment with the concept of subtractive color mixing, wherein colors are created by subtracting wavelengths of light. The discovery that cyan, magenta, and yellow were the primary subtractive colors paved the way for the development of color printing techniques.

- The Key to Precision – Black:

While cyan, magenta, and yellow could produce a wide range of colors, achieving deep blacks and accurate grayscale tones remained a challenge. In the early 20th century, the addition of black as the key (K) color in the CMYK model addressed this limitation, enabling printers to achieve richer contrasts and finer details in printed materials.

- Technological Innovations:

Technological advancements like offset printing in the late 19th century and digital printing in the late 20th century further propelled CMYK’s evolution, enhancing speed, efficiency, and quality. Today, CMYK is the standard in various printing processes worldwide, from offset to digital printing, catering to a wide array of materials such as magazines, packaging, and advertisements. Looking forward, ongoing innovations, such as eco-friendly practices and integration of augmented reality and variable data printing, promise to continue shaping the future of CMYK printing with endless possibilities for creative expression and communication.

3. What is the mechanics of CMYK printing?

Subtractive Color Principle:

When sunlight hits an object, the object absorbs some of the light and reflects the rest. The reflected light constitutes the subtractive color model, which determines the color of the object and is fundamentally different from the RGB model. Following the subtractive model, the CMYK color mode, suitable for printing, is derived. During printing, typically on white paper, the paper is opaque, preventing light from passing through. This is why cyan, magenta, yellow, and black, the four printing colors in CMYK, are sequentially applied in industrial offset color printing. The actual printing process involves placing small, closely spaced dots on the printing substrate. Once combined and viewed from a distance, these dots are perceived by the human eye as a colorful image.

Step-by-Step Process:

- 1. Preparation of Digital Artwork:

The CMYK printing process begins with creating digital artwork using design software such as Adobe Photoshop, Illustrator, or InDesign. During this process, designers use CMYK color profiles to ensure that the colors in the design can accurately translate to the printing material.

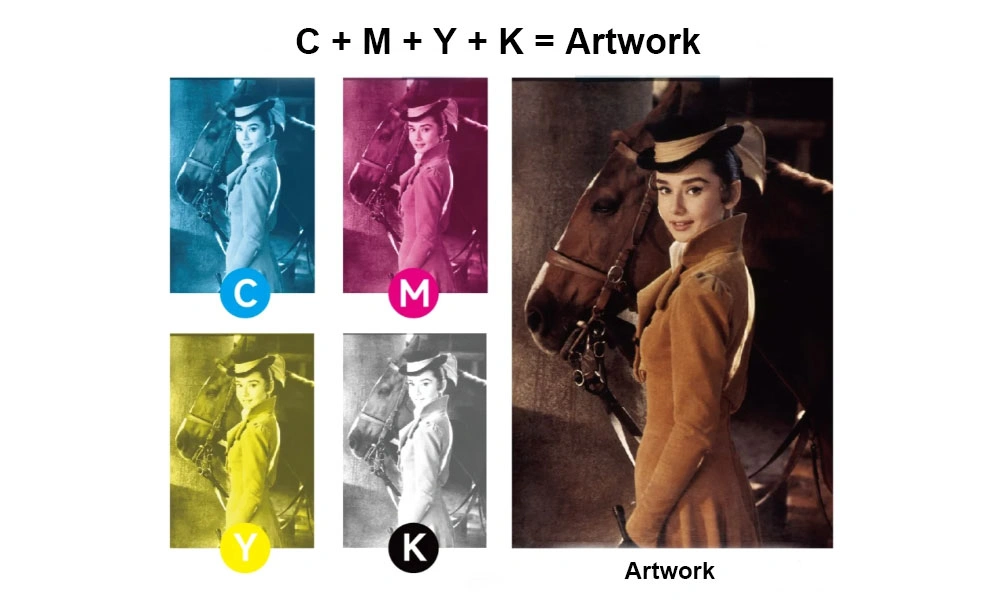

- 2. Color Separation:

Once the digital artwork is ready, it undergoes color separation, a process where the design is broken down into separate color channels for cyan, magenta, yellow, and black. Each color channel represents the amount of ink needed for that particular color component.

- 3. Plate Production:

Based on the color-separated images, printing plates are created for each color channel. These plates contain the negative image of the design, with areas to be printed in each ink color etched onto the plate’s surface. Modern printing technologies often utilize digital plates for increased efficiency and accuracy.

- 4. Ink Application:

During the printing process, the printing press applies the four ink colors to the printing surface in successive layers. The ink is transferred from the printing plates to the printing substrate, whether it’s paper, cardboard, or another material.

- 5. Color Mixing and Reproduction:

As the ink colors are applied in layers, they interact with each other and with the white surface of the printing substrate. Through subtractive color mixing, the cyan, magenta, yellow, and black inks combine to produce a wide range of colors, shades, and tones, faithfully reproducing the colors of the original digital artwork.

- 6. Drying and Finishing:

Once the printing process is complete, the printed materials undergo drying to ensure that the ink adheres properly to the substrate. Depending on the desired finish, additional processes such as coating, laminating, or binding may be applied to enhance the durability and appearance of the final printed products.

4. Decoding CMYK Numbers

CMYK numbers are used to represent the amount of each ink color used in printing. In color printing, colors are created by combining different proportions of four primary ink colors.

Here’s what each component represents:

Cyan (C): In CMYK printing, the “C” value indicates the percentage of cyan ink applied to the printed surface. For example, if the CMYK value for cyan is 50%, it means that half of the available space for cyan ink will be filled with cyan ink.

Magenta (M): The “M” value in CMYK denotes the percentage of magenta ink used. If the CMYK value for magenta is 75%, it means that 75% of the available space for magenta ink will be filled with magenta ink.

Yellow (Y): The “Y” value represents the percentage of yellow ink applied. For instance, if the CMYK value for yellow is 25%, it means that 25% of the available space for yellow ink will be filled with yellow ink.

Key (Black) (K): The “K” value in CMYK indicates the percentage of black ink used. If the CMYK value for black is 100%, it means that the entire available space for black ink will be filled with black ink. So, when you see CMYK numbers like “C: 50%, M: 75%, Y: 25%, K: 100%”, it means that the printing process will use 50% cyan ink, 75% magenta ink, 25% yellow ink, and 100% black ink to reproduce the desired color. These values help ensure that the colors printed on paper match the colors intended by the designer or artist.

5. Understanding the Significance of Color Gamut in CMYK Printing

In printing, vibrant colors are crucial for high-quality prints that engage the audience and convey messages effectively. The color gamut, particularly in CMYK printing, plays a central role in achieving this. CMYK printing’s color gamut represents the spectrum of colors achievable with Cyan, Magenta, Yellow, and Black inks. Let’s explore its significance and role in the printing process.

- Color Accuracy and Consistency:

By defining the achievable color spectrum, the color gamut can serve as a reference for maintaining color consistency across different printing devices, substrates, and viewing conditions, as well as matching the colors of original artwork or designs.

- Optimizing Color Selection:

Understanding the limitations of the CMYK color gamut helps designers control colors within the achievable range for printing, thus enhancing the feasibility of their designs.

- Color Management and Conversion:

Color management systems utilize color gamut data to convert colors between different color spaces, like translating RGB to CMYK for printing. Understanding CMYK’s color gamut enables accurate color translation, reducing color shifts and discrepancies across different color spaces.

- Predicting Print Results:

Visual representations of the color gamut help designers and printers predict how colors will appear when printed. By analyzing color gamut visualizations, designers can anticipate any potential color shifts or inaccuracies and make informed decisions about color adjustments and optimizations to achieve the desired print results.

6. Unveiling the Advantages of CMYK Color Model

- Extensive Color Palette:

CMYK provides an extensive and varied array of colors. Through the amalgamation of varying proportions of these four hues, printers can replicate a broad spectrum of shades, guaranteeing precise color representation of the initial designs in printed materials.

- Subtractive Color Mixing:

CMYK uses subtractive color mixing, where colors are formed by subtracting light wavelengths, which suits printing as inks are applied to a surface. By subtracting varying levels of cyan, magenta, yellow, and black from white light, CMYK ensures accurate color reproduction in prints.

- Enhanced Color Accuracy:

The CMYK color model offers superior precision in replicating colors compared to alternative color models. This is particularly important in fields such as graphic design, advertising, and photography, where color fidelity is crucial for conveying messages effectively and maintaining brand consistency.

- Cost-Effectiveness:

Using CMYK for printing is cost-effective in terms of both production and materials. By utilizing a standardized color model, printers can streamline their workflows and reduce the need for custom color mixing. Additionally, CMYK inks are readily available and cost-efficient, making them accessible to printers of all sizes.

- Compatibility with Printing Technologies:

CMYK is compatible with various printing technologies, including offset printing, digital printing, and color photocopying. Whether it’s high-volume commercial printing or on-demand printing for small-scale projects, CMYK provides flexibility and versatility across different printing platforms.

As the preferred choice in the printing industry, CMYK continues to play a pivotal role in bringing vibrant and captivating designs to life on paper and beyond.

7. How to ensure color accuracy in CMYK printing?

In printing, color accuracy is vital for professional-quality results that reflect the intended design. CMYK printing, the industry standard, demands meticulous attention to detail to maintain color precision. Let’s delve into key steps and techniques for ensuring color accuracy in CMYK printing.

1. Start with a Calibrated Monitor:

Color accuracy begins with your monitor. Ensure that your computer monitor is properly calibrated using a hardware calibration device or software calibration tools. Calibrating your monitor ensures that the colors you see on the screen remain consistent with the CMYK colors used for printing.

2. Work in a Color-Managed Environment:

Use design software that supports color management and work in a color-managed environment. Configure color settings to use CMYK color profiles appropriate for your printing process and paper type. This ensures consistency in color representation across different devices and software applications.

3. Utilize Soft Proofing:

Take advantage of soft proofing features in design software to simulate how colors will appear in the final printed product. Soft proofing allows you to preview how CMYK colors will look on screen and identify any potential color discrepancies before sending the artwork to print.

4. Request Printed Proofs:

Request printed proofs from your printing service provider before finalizing the print run. Printed proofs provide a tangible representation of how colors will appear on the actual printed materials. Review the proofs carefully to ensure color accuracy, clarity, and overall print quality.

5. Consider Pantone Matching System (PMS) Colors:

For precise color matching, especially for brand colors or specific hues, consider using Pantone Matching System (PMS) colors. PMS colors are standardized and can be converted to CMYK for printing. They ensure consistency in color reproduction across different printing jobs and materials.

6. Communicate with Your Printer:

Maintain open communication with your printing service provider throughout the printing process. Provide detailed color specifications, including CMYK values, any special requirements, and reference samples if available. Clear communication helps ensure that the printer understands your color expectations and can make adjustments as needed.

7. Perform Test Prints:

Conduct test prints on the same printer, paper, and settings that will be used for the final print job. Test prints allow you to evaluate color accuracy, print quality, and other factors before proceeding with the full print run. Make any necessary adjustments based on the test prints to achieve optimal results.

8. Exploring the Diverse Applications of CMYK Color Mode

From traditional print media to digital design, and textile printing, CMYK plays a vital role in bringing visual concepts to life with accuracy and vibrancy. By understanding the diverse applications of CMYK, designers, artists, and marketers can leverage its capabilities to create impactful visuals that captivate audiences and convey messages effectively.

- Printing Industry:

CMYK is the primary color mode used in offset and digital printing processes. Each ink color (cyan, magenta, yellow, and black) is layered to create a wide spectrum of colors, allowing for vibrant and accurate reproduction of images and text. From business cards and brochures to posters and banners, CMYK ensures consistent and high-quality prints across various mediums.

- Packaging Design:

CMYK plays a crucial role in packaging design, where color accuracy and visual impact are paramount. Whether it’s food packaging, cosmetics, or product labels, CMYK enables designers to create eye-catching designs that attract consumers’ attention on store shelves. Additionally, CMYK printing allows for the incorporation of intricate details, gradients, and special effects to enhance the overall appeal of the packaging.

- Digital Design and Advertising:

While RGB (Red, Green, Blue) color mode is standard for digital displays, CMYK remains essential for designing print materials in the digital realm. Designers often work in CMYK when creating marketing materials such as flyers, posters, and magazine advertisements. By designing in CMYK from the outset, they ensure that the colors will translate accurately from screen to print, maintaining brand consistency across different platforms.

- Textile Printing:

In the realm of textile printing, CMYK is used to transfer designs onto fabrics, garments, and other textiles. This process, known as dye-sublimation printing, involves printing the design onto a transfer paper using CMYK inks and then transferring the design onto the fabric using heat and pressure. CMYK offers versatility in textile printing, allowing for intricate patterns, vibrant colors, and durable prints that withstand washing and wear.

8. Additional knowledge around CMYK

Q1. Is it possible to utilize CMYK colors for printing with an inkjet printer?

Yes, inkjet printers can print using CMYK colors. Ensure your printer supports CMYK printing, use design software like Adobe Photoshop or Illustrator in CMYK mode, adjust printer settings, use compatible CMYK ink cartridges, and choose appropriate printing paper for best results.

Q2. What are the commonly used file formats for CMYK printing? Which one is the best?

| Formats | Application | Advantages |

| TIFF (Tagged Image File Format) | widely used in professional printing workflows | They offer high-quality compression without loss of image data, making them suitable for retaining color accuracy and detail in printed materials |

| EPS (Encapsulated PostScript) | commonly used for vector graphics and illustrations in CMYK color mode. | support high-resolution printing and are often preferred for logos, illustrations, and other graphics that require scalability and precise color representation |

| PDF (Portable Document Format) | versatile for both print and digital distribution | PDF/X-1a and PDF/X-4, are specifically designed for print production and ensure proper handling of CMYK color data, fonts, and graphics |

| PSD (Photoshop Document) | commonly used for photo editing and design projects intended for CMYK printing | PSD files are native to Adobe Photoshop and support CMYK color mode along with layers, masks, and other editing features |

| AI (Adobe Illustrator) | commonly used for creating logos, illustrations, and other vector artwork intended for CMYK printing | AI files are native to Adobe Illustrator and support CMYK color mode for vector-based graphics. |

| INDD (Adobe InDesign) | used for creating layout designs for print publications such as brochures, magazines, and books | INDD files are native to Adobe InDesign, support CMYK color mode and enable precise control over typography, layout, and color |

As for which file format is the best for CMYK printing, it ultimately depends on the specific requirements of your printing project and your preferred design software. Each file format has its advantages and is suitable for different types of content and workflows. For most print production workflows, PDF is often considered the best choice due to its versatility, compatibility, and support for CMYK color mode. However, it’s essential to ensure that your chosen file format meets the technical requirements of your printing service provider and is compatible with your design software and workflow.

Q3. Is it possible to create custom CMYK color samples?

Yes, it is possible to create your own custom CMYK color swatches to match specific color preferences, brand guidelines, or design requirements. You can create and save custom CMYK color swatches using popular design software applications such as Adobe Photoshop, Illustrator, and InDesign.

Q4. What are the common CMYK printing color profiles?

In CMYK printing, various color profiles ensure accurate color representation and reproduction across devices and processes. Common profiles include SWOP for commercial offset printing, GRACoL for enhanced accuracy, ISO Coated v2 for general printing on coated paper, and ISO Uncoated for uncoated paper stocks. These standards, prevalent in different regions, such as SWOP in North America and ISO Coated internationally, guide color management. Custom profiles may also be tailored for specific needs. Selecting the appropriate profile is crucial for precise color reproduction and consistency across print materials, ensuring high-quality results tailored to printing processes, paper types, and regional standards.

Q5. Is it possible to utilize CMYK colors in digital artwork?

Yes, CMYK colors can be used in digital artwork, especially for print production. Software like Adobe Photoshop, Illustrator, and InDesign supports CMYK mode for creating digital artwork. This is helpful for designing printed materials such as posters, brochures, business cards, and packaging, ensuring accurate color representation in the final print.

Q6. How to checke if a file is in CMYK format?

To verify a file’s color mode, there are several methods: Firstly, open the file in design software like Adobe Photoshop, Illustrator, or InDesign, and check for the color mode indication in the software’s interface. Additionally, you can right-click on the file to access properties on Windows or “Get Info” on Mac, and look for color mode details. Another approach is to open the file in an image viewer or preview application, where color mode information may be displayed in the file details or metadata. If the file is intended for printing, consulting with a printing service provider can also confirm its CMYK format, as they possess expertise in analyzing various file formats and color modes.

Q7. When using the CMYK color mode, is it possible to achieve a transparent background?

No, it’s not possible. Unlike the RGB (Red, Green, Blue) color mode which supports transparency through the Alpha channel, CMYK (Cyan, Magenta, Yellow, Black) creates colors by subtracting varying amounts of ink from a white background and does not have a built-in transparency mechanism.

Q8. Can CMYK colors be used for screen printing?

Yes, CMYK colors can be used for screen printing. Although screen printing typically involves using spot colors (pre-mixed inks formulated for precise colors), however, in certain cases, CMYK screen printing is utilized, especially for designs with complex gradients, photographic images, or multicolored artwork where replicating with spot colors alone is challenging. CMYK screen printing involves using halftone screens to simulate the effect of different ink densities, similar to how CMYK printing works in offset or digital printing.