Embossing and debossing are printing techniques that utilize pre-made engraving models and the application of pressure to create a three-dimensional effect on the surface of paper.

Embossing involves imprinting a raised, three-dimensional design or pattern onto a material. By pressing or stamping a specific design onto the surface, it creates a visually prominent image or pattern that adds texture and allure.

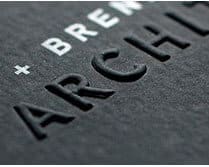

On the other hand, debossing creates a recessed impression by pressing or debossing the design into the material, resulting in a concave effect that is lower than the surrounding area. This technique produces a unique visual and tactile impact through the formation of sunken images or patterns.

The Embossing & Debossing process offers several effects. The interplay of raised and recessed patterns adds depth and vividness, creating a more pronounced artistic effect. Furthermore, it enhances the overall structure, rendering clear and intricate levels.

The Embossing & Debossing process finds applications in packaging design, such as custom handbags and gift boxes. By ensuring a smooth and visually appealing surface, it reinforces the brand image and imparts a high-end aesthetic. Through the creation of various textures, images, and subtle three-dimensional effects, the combination of embossing and hot stamping complements each other, adding a touch of elegance and fashion to the product packaging.

Key features of the Embossing & Debossing process include its ink-free production method, which relies solely on pressure. As a result, it does not cause any environmental pollution, making it an environmentally friendly process that aligns with customer’s eco-consciousness. The embossing process is an excellent choice for industries that prioritize green and sustainable practices.