What is a corrugated box

If your business activities often need to ship a variety of products, then the choice of packaging is definitely a problem you can’t escape. And among the different packaging materials, you’ll find corrugated boxes used in various ways throughout the packaging industry. Corrugated boxes, also known as paper boxes, often worked as packaging for easy shipping. The widespread use of corrugated paper boxes is the result of many factors, not just because of its low cost but also because of the structure of the corrugated paper.

This blog aims to explain and clarify everything you need to know about cardboard. Everything is explained, from flutes to material, liners to the number of walls. Keep reading to learn about the different types of corrugated cardboard and their uses.

The structure of the corrugated paper

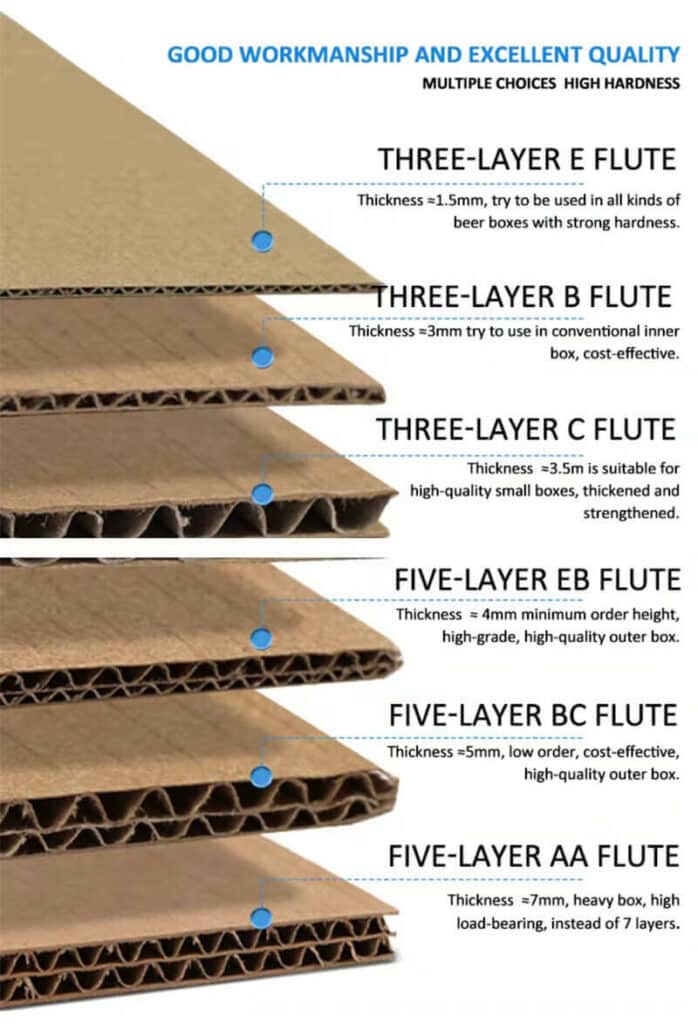

Corrugated cardboard usually consists of three layers of fiberboard, the outer two layers are two sheets of liner board, and a piece of corrugated cardboard is sandwiched in the middle. This corrugated cardboard is called a flute. Three layers of cardboard are held together with an adhesive to form corrugated cardboard. When combined with liner and adhesives, these undulating structures, along with the spaces within the grooves, provide the product with cushioning and protection, allowing the corrugated board to hold a great deal of weight in practical applications. Therefore, it is easy to understand that larger flutes will provide greater strength while smaller flutes closer together benefit from better printability and foldability. Here are descriptions and details of each corrugated flute size. A and B are relatively common flutes among all these types, and I will also introduce these two flutes to you in detail.

A flute is 1/4 inch thick, which is the thickest corrugated flute design. Due to its thickness, the A-flute is often used as a box for fragile products as it provides maximum cushioning for the product inside. In addition, the A-flute is also widely used in other applications due to its excellent stiffness qualities and short-column compression resistance.

Compared to A-flute, B-flute is 1/8 inch thick, has a lower crown height, and has more grooves per foot, so B-flute contacts the liner at more points. This extra support provides a firm, flat surface for high-quality printing and die-cutting. Coupled with the excellent puncture and crush resistance properties of the B-flute and taking up less warehouse space, the B-flute can be the first choice for high-speed automatic packaging lines as well as liners, dividers, partitions, and other forms of inner packaging. It is commonly used for mailings and some special displays, such as beer and wine cases. B-flute is one of the most commonly used board types in packaging applications.

Besides that, C-flute is 3/16 inch thick, which means it can provide better stacking strength when used in lightweight products—widely used for shipping cases.

E-Flute is 1/16 inch thick, a strong alternative for paperboard folding cartons.

F-flute was developed for small retail packaging and is sometimes used interchangeably with E-flute.

Generally speaking, the paper used for backing paper is mainly kraft paper. Kraft paper is made from coniferous trees, and due to the “virgin” fibers, it is the strongest type of paper and the easiest to print on. Therefore, when choosing materials for the production of corrugated boxes and packaging, it is the most commonly used outer lining material. In addition, the paper types that can be used for the outer lining and the inner lining when making cardboard include

| CHIP (C): | Waste based liners |

| FULLY BLEACHED WHITE (BW) | Fully bleached Kraft liner |

| WHITE TOP (WT) | White coated recycled liner |

| MOTTLED KRAFT (MK) | Mottled white Kraft |

| OYSTER (OY) | Mottled test liner |

| SEMI CHEM (SC) | Virgin fibers using neutral sulphite semi-chemical process |

| WASTE BASED (WB) | 100% recycled fibers |

Types of corrugated box

A standard sheet of corrugated cardboard is made of 3 structures. A sheet of corrugated or “fluted” material in the center, placed between two layers of paper—the outer and inner lining. But corrugated cardboard is not only composed of the various structures mentioned above; different flutes can also combine it to form single-layer corrugated cardboard; an increasingly popular way is to combine two grooves are grouped together. This meets highly specific packaging needs and makes the packaging more robust and durable.

Single-wall board is the most common type of corrugated board. If someone is talking about corrugated cardboard, there’s a good chance they’re talking about the single-wall board. It consists of two layers of outer lining and a middle layer of corrugated base paper, which are lining, grooves, lining in order, usually used for transporting cartons, and double-layer wallboard, which has two layers of corrugated grooves and three layers of Lined, very durable. The order is lining, groove, lining, groove, lining, usually used in industrial cartons. There is also a more common three-layer wall panel, which is strong enough to replace wooden boxes. This corrugated cardboard is generally a reliable choice for transporting chemicals or items that require special handling. Its order is the lining, grooves, linings, grooves, and linings, often used as shipping boxes and chemical containers.

Conclusion

The ribbed corrugated cardboard sandwiched between two pieces of cardboard is designed to support a great deal of weight. Not only is this good for shipping, but it also plays an important role in supporting food weight in pizza boxes and corrugated cardboard takeout boxes. This cardboard groove structure also plays an integral role in protecting items and preventing damage during transport. PACKFANCY is your leading gift packaging solution provider; we can customize gift packaging for your products and specific needs. We will do our best to meet your packaging requirements.