Flexography, also known as flexo printing, is a printing method that uses a flexographic plate and transfers ink through an anilox roller to print and belongs to the letterpress type. The printing plate generally adopts a photosensitive resin plate with a thickness of 1-5mm. Inks are divided into three categories: water-based inks, alcohol-soluble inks, and UV inks. With the development of the commodity economy and the continuous improvement of people’s living standards, the packaging and printing industry is also developing in the direction of high-end, fine, and multi-variety. However, offset printing, and gravure printing occupy a considerable market share, while flexographic printing started relatively late in the printing industry, especially in the printing of high-end products. Up to now, after decades of continuous and stable development, with the constant application of new technologies, flexographic printing has made significant progress, and the product quality has directly caught up with offset printing and gravure printing. People no longer think that flexographic printing can only print some low-end printed products with solid and thick lines and has a very strong market competitiveness.

There are two main technologies for flexo printing, including Flexo Center Roll Technology and Flexo Belt Technology. The first one is the most advanced web technology. Central cylinder printing presses print with the aid of sleeves containing printing plates. In continuous printing lengths up to 2.06 meters, images can be printed at high speed with great precision and low waste levels. And flexo Belt Technology is an innovative web-fed process developed and patented specifically for the requirements of corrugated board production. Particularly large print formats up to 4.5 meters can be produced mainly in one piece and cost-optimized. The printing plates are mounted on the endless belt.

Why choose flexo to print packaging

The most significant benefit of flexographic printing lies in its contribution to the environment. Because the ink used in flexographic printing is environmentally friendly, which makes it has been widely used in food packaging printing and has a bright future. We know that in the traditional printing industry, due to technical limitations, many printing factories tend to purchase some printing materials at low prices that are not conducive to environmental protection to reduce costs. Flexographic printing mostly uses water-based inks, UV inks, and drunk soluble inks that are non-toxic, have no residual latent agents and have no environmental pollution. It adapts to the requirements of environmental protection and eco-friendly packaging, and the issue of environmental protection has always been a big problem hindering the sustainable development of the printing industry. And with the environmental issue that has attracted more and more attention from the public as the development of society, the advantages of flexographic printing are increasingly obvious.

In addition, flexographic printing is uniquely flexible and economical, and this printing method has great flexibility to transfer liquid or grease inks to almost any type of material.

Many countries consider it the ‘best and most promising’ printing method. Almost all paper and plastic packaging products can be printed by flexo printing. It can not only print all kinds of paper but also aluminum foil, plastic film, self-adhesive paper, cellophane, metal foil, textiles, etc. For offset printing, other media cannot or are not easy to print except for paper.

Compared with other printing methods, flexo printing has an irreplaceable advantage in simple printing images that do not require high quality. This printing process is also widely used in elastic and stretchable films, wool and cellulose, and various Printing of special colors on plastic and aluminum. In the high-end market, it can almost reach the quality of gravure and offset printing. Due to its versatility, flexographic printing has become one of the most commonly utilized. Flexo printing’s versatile image carriers easily handle either method.

Types of flexo printing boxes

As we all know, the current business has developed to the extent that all packaging needs to be printed. And printing is an indispensable part of product packaging; it is also a way to promote brands and introduce products. Flexo printing is used in almost all areas of packaging printing. Printing on paper and corrugated boards can achieve very good printing results, and flexo printing is especially suitable for solid colors and graphic displays. Flexo boxes can be produced on various paperboards, including white and brown kraft boards. As corrugated paper benefits from the combination of lightness and durability of the material, it is very suitable for transportation. It’s natural brown underside also looks very eco-friendly. In fact, they are completely renewable. In addition, the cost of corrugated paper is lower than other materials, and flexo printing has a unique advantage in low cost, so it is a natural result that flexo printing boxes are favored by manufacturers.

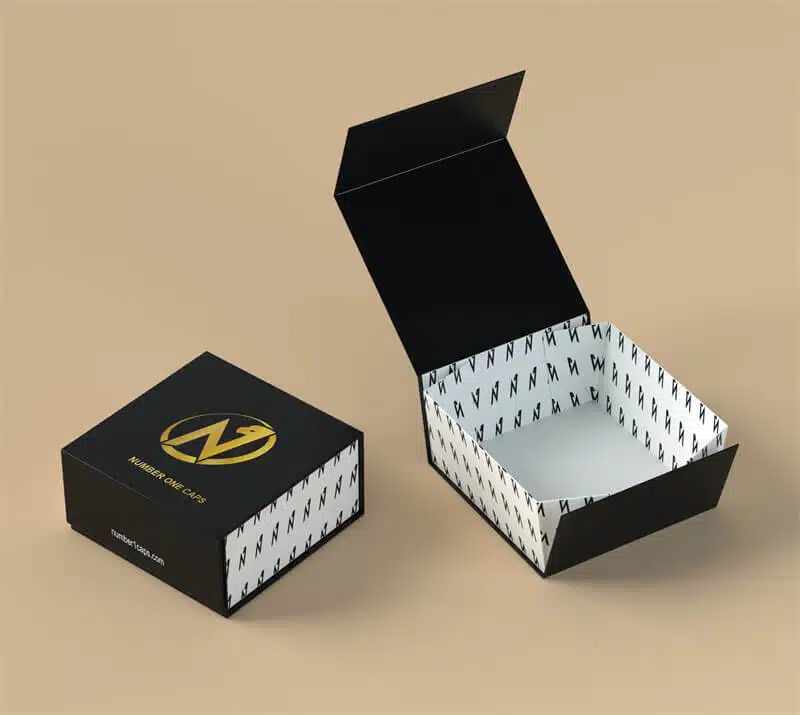

In addition to corrugated paper, flexo printing is also far and wide used in various packaging printing products. Self-adhesive labels are also the main products of flexographic printing machines, which can complete almost all label printing processes. In addition to the two mentioned above, flexo also has a good performance in the printing of subscription boxes, shipping boxes, jewelry boxes, clothing boxes, and another packaging.

Conclusion

Flexographic printing can afford smaller orders because its printing plates are more economical than gravure cylinders and are easier to replace. High-resolution flexo printing enables quick changeovers of print jobs, shortening the design-to-print time cycle.

These advantages bring more choices for packagers, especially in the current market environment where the packaging market emphasizes personalization, regionalization, and regular promotional activities. Printing of more complex colors can be achieved, improving the realism of the image, and the tone is more attractive, vivid, and softer. Packaging managers can use the flexographic printing process to achieve more eye-catching product effects and improve the contrast between the product and background colors.

I believe that through the above introduction, you have fully understood what flexo printing is, and have your own understanding of flexo boxes. PACKFANCY is a manufacturer of custom gift packaging, and we have sufficient experience in this area. If you are looking for a suitable gift wrap, contact us any time.